THREE™ Scans and Reviews

Have a scan you're proud of, or want to review THREE? Reach out to us at info@matterandform.net

Matter and Form 3D Scanner Sample Scans

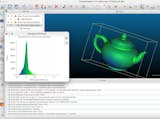

Explore real 3D scans captured with the Matter and Form THREE 3D Scanner. Download high-quality, detailed 3D models and see the scanner’s precision in action. Perfect for 3D printing, modeling, and digital design.

This is the fifth 3D scanner have owned over the past 12 years. It addresses all the limitations I had with previous scanners while being easy to use. Lots of options to maximize the quality of the scan while minimizing scan time for the wide range is objects we scan. The versatility is beyond what we had hoped for when we backed the kick starter project

THREE is a powerhouse, plain and simple. I've been scanning professionally for almost 5 years now, having used offerings from Artec, Einscan, and Faro. Its ability to capture surfaces that most other scanners struggle with, the detail retrieval, ease of use, flexibility and painless processing, are all worth noting on their own. But putting all of that under a prosumer price point makes this powerful little scanner something to behold. Plus, the synchronized turntable is a cherry on top of the sundae that is THREE.

This review is of the initial release and there are areas lacking like texture capture, but it can be improved on the user's side with decent lighting. Amazingly, this is the only real gripe I've had with it and it's minor. There were concerns on reddit before its launch that the 16GB of storage would be too little, but after scanning everything that was scannable on my desk at the highest density possible, I'm 22 projects in on the scanner and the storage is not even half full. I'm not sure how they are doing it, but it seems they have tapped into quantum physics and are storing scan data in a pocket dimension (don't quote me on that).

In summary, I am exceedingly happy with what THREE can do and I look forward to scanning literally everything I can get my hands on!

Hello Alex and Trevor

I have been meaning to write for some time to give you some feedback on my experience with the Matter and Form Three - 3D Digitizer.

I began my 3D digitizing experience in 1985 when I began developing the software to make custom shoe lasts. A shoe last is the form that a shoe is molded over which gives it all the characteristics of the size, heel height, toe shape etc. I began my shoe making career in early 1970s when I started making Custom Sandals. By 1985 I had discovered the possibility of using 3D software to create solid models that could be modified and produced to give the exact, fit or at least 95% correct, leaving very little modification work to achieve the perfect fit.

So I began my journey to create the software that would be required for this very special application. I ran into many problems trying to modify existing programs that would accomplish my goal. After 10 years of research and great deal of frustration I partnered with a software company in France that was a conglomeration of three fashion shoe companies. They already had the base software for making 2D patterns. They could make 3D models in standard sizes , but they lacked the input for modifying shoe lasts to the measurements of the foot.

So I joined the team of programmers and began working on 3D modeling based on the properties of the individual foot. We had to make one for the left foot and one for the right foot and they were often quite different.

I had created a library of last models that we would use as the basis for designing and constructing the custom footwear. I created my collection of basic models for men and for women, they were for boots, shoes and other specialty footwear. There were 68 last models in all.

Some of the original models were made of wood some were plastic. At that time in the late 1990s a 3D digitizer was selling for about $150,000 dollars. So I packed up all my models and sent them to France to be digitized.

So now we have to fast forward 25 years to the modern era. During this period of time I started a ShoeSchool where I had over 500 students that I taught how to make shoes. As part of the ShoeSchool I collected over a thousand pair of shoe lasts.

After running the ShoeSchool for over 40 years it now became time to retire. And the question became what to do with all the shoe lasts? So I began to research the availability of modern 3D digitizing technology. That is when I discovered Matter and Form Three, 3D digitizer. I purchased one and have been using it for over a year. One day last week I was backing up all of my data files and discovered that I had over 400 scans to back up. So with that experience under my belt I realized that my testimonial letter was way overdue.

So I am writing this letter as a testimonial for anyone that is looking for a highly accurate easy to operate 3D digitizer. The Matter and Form Three is the answer for anyone looking for a solution for their scanning needs.

Plus, they have great technical support to help you out so can get going!

Alan Zerobnick

CEO Digilast

December 28, 2025

- All-in-one solution means I can use it with any computer without needing to worry about software updates or processing. This has been the thing I absolutely love. The scanner just works as intended - I haven't had to deal with downloads or connectivity or any of that.

- Ease of use: Calibration of the turntable was super easy, setting up the scan was intuitive. Everything is just very intuitive for a novice like me. The included turntable with the plug-and-play interface with the scanner is also just so nice.

- Post-Processing: Multi-scan auto alignment and exporting have been virtually flawless. It's nice to click an "Auto" button and actually have it be auto.

- Scan Quality and Accuracy: My first scan was a matte black object with a reflective silver metal lip. Calibration was easy, and the scan came out beautifully on the first try. The object is about 70mm L x 40mm H x 28mm D with pretty intricate features and a draft angle (injection molded). The scanner picked up all the little features and measuring the accuracy I'm within 0.1mm on everything I can readily measure with my nice pair of gauge-block tested Mitutoyo calipers.

- Support: I had an issue the first week where MAF pushed a SW update that rendered the turntable non-functional. I reached out. They responded quickly, and 12 hours after my initial issue they let me know a hotfix was deployed. The scanner is back to being fully-functional.

What could use a little work IMO:

- During focusing or initial placement/calibration with the object, it was clear that I had to turn the exposure really low for my lighting and my object to get a decent scan. However, doing so made it difficult to "find" my object via the scanner camera since the light was low. It would be nice if the exposure and light was at full blast during the initial placement and focus selection even if it is set low for the scan.

- Exposure setting: My object had some edges that turned red with very little exposure, probably because of a combo of my lighting and the angle of the edges. As recommended, I performed a scan with the exposure dialed to prevent any "red" in the scan setup. That scan came out well still, but I tried one with the exposure bumped up into the red a bit, and the scan came out even better with no signs of any issues. This could be MAF being conservative with this setting to make sure that the scan doesn't have issues, but I found it to be a bit too conservative in my testing. Not really a criticism, more of a comment.

I'm really glad I purchased the MAF THREE. I have experience with 3D scanning using photogrammetry and iPhone LiDAR, but when I purchased a 3D printer, I wanted a high-precision 3D scanner. After considering various products, I'm confident that choosing the MAF THREE was the right decision.

Join our newsletter

3D scanning tips and tricks, news and THREE!

- Choosing a selection results in a full page refresh.