As I taught my students in 3D design and printing classes, their goal should be to first LEARN their tools and then USE their tools.

And, that is exactly what I am trying to do with my THREE.

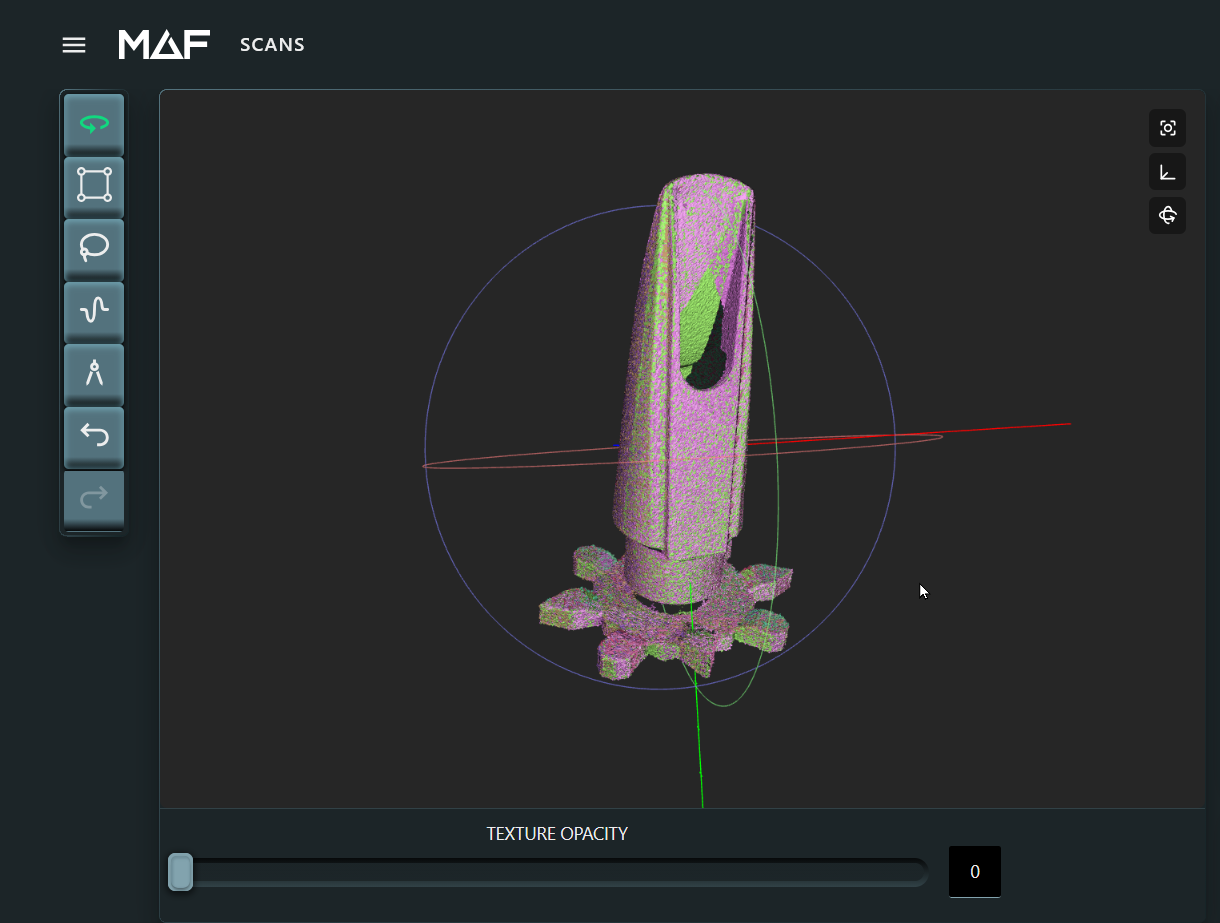

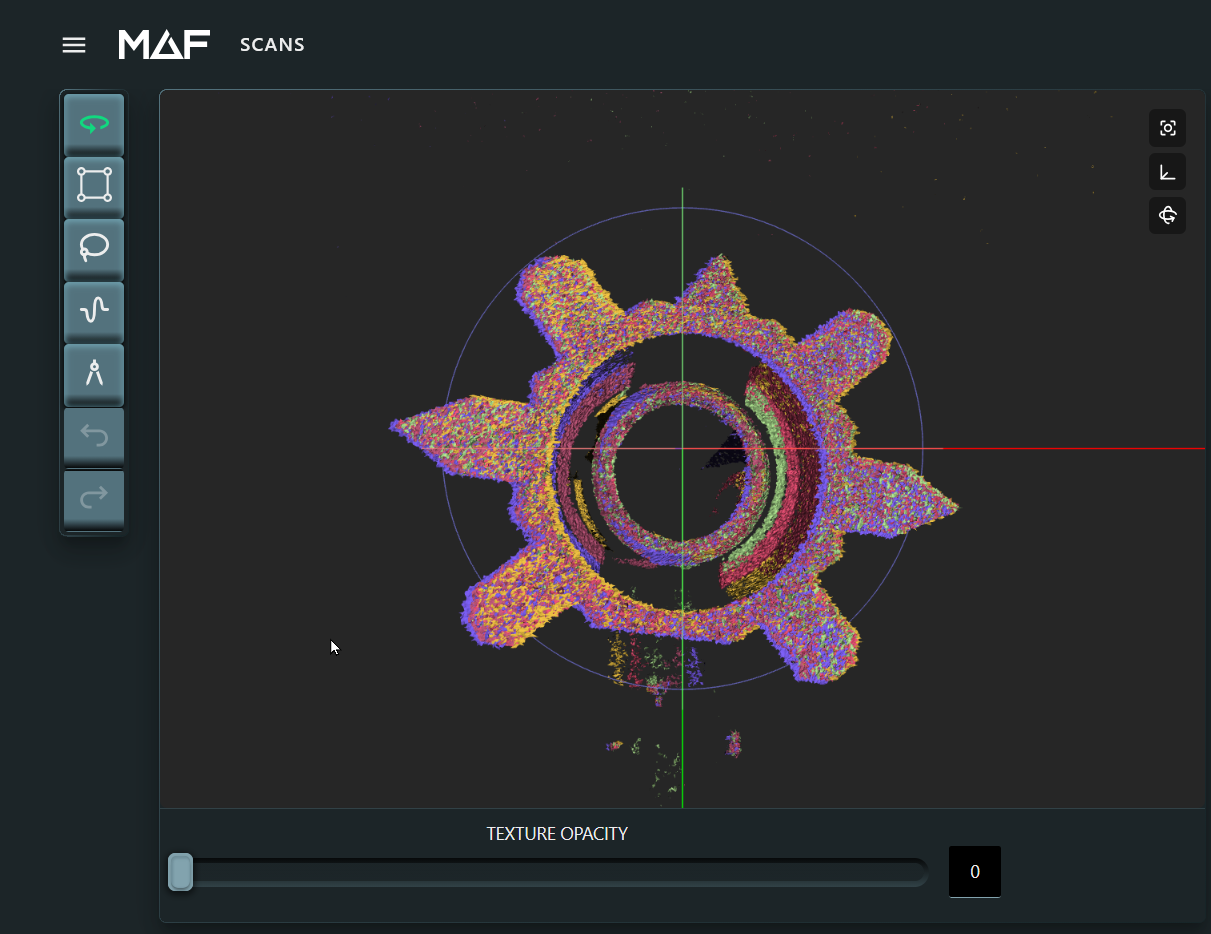

I don't mind limiting what I initially scan if experimenting with the THREE will give me insights that I can use in the future for many scans. That learning scan could be just about anything. In my case I'm using a saxaphone mouthpiece.

My goal is to explore and understand the THREE's feature based approach to alignment.

And, I am working under one assumption that may or may not be correct.

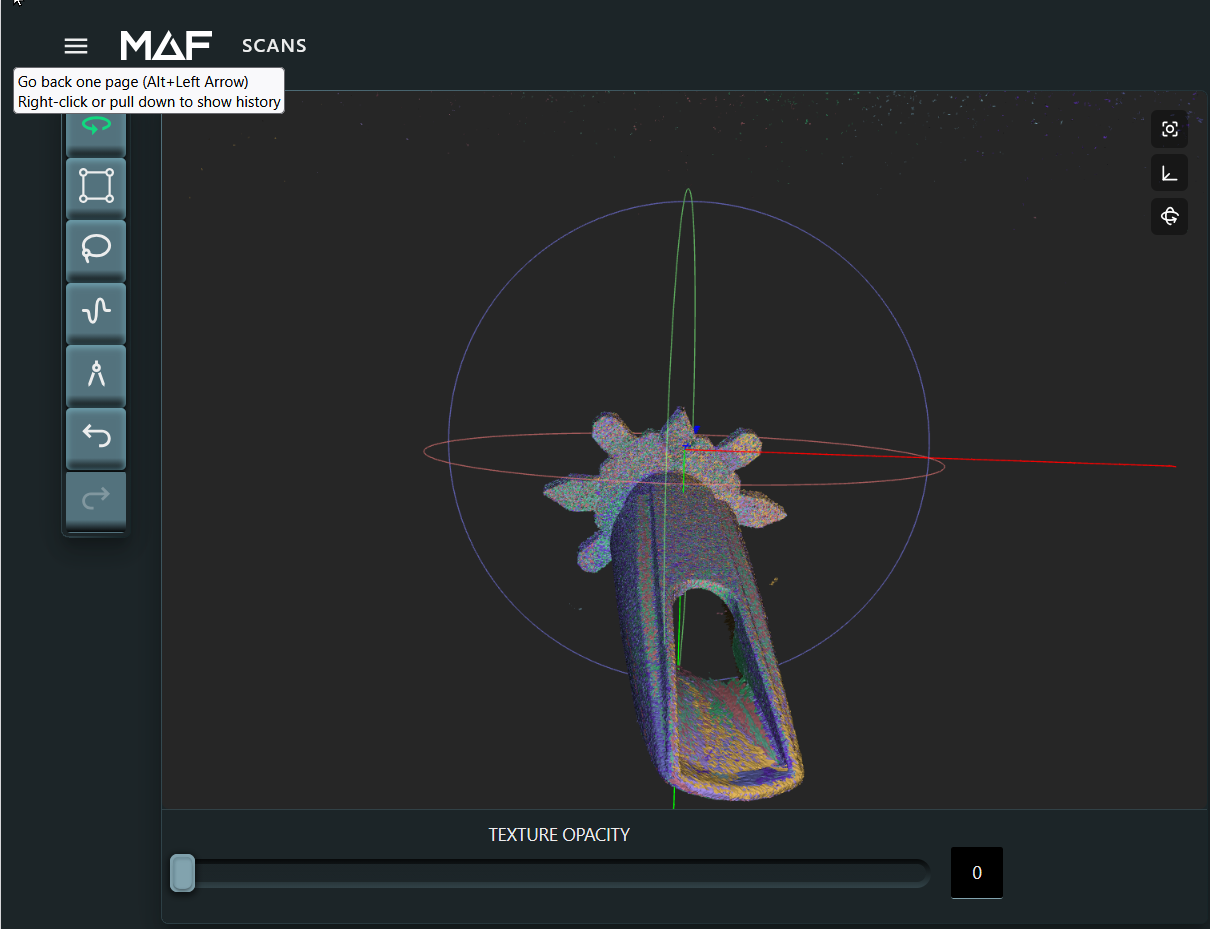

"Reference Objects should always move in relative position with the object being scanned as that object is changing orientation."

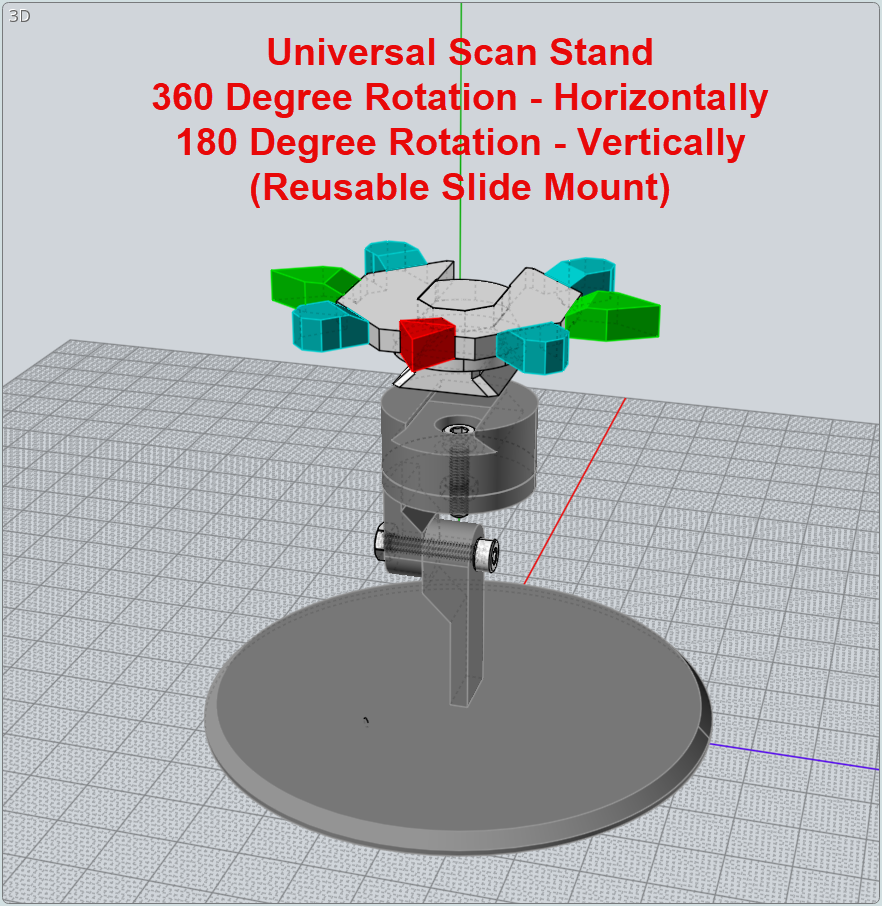

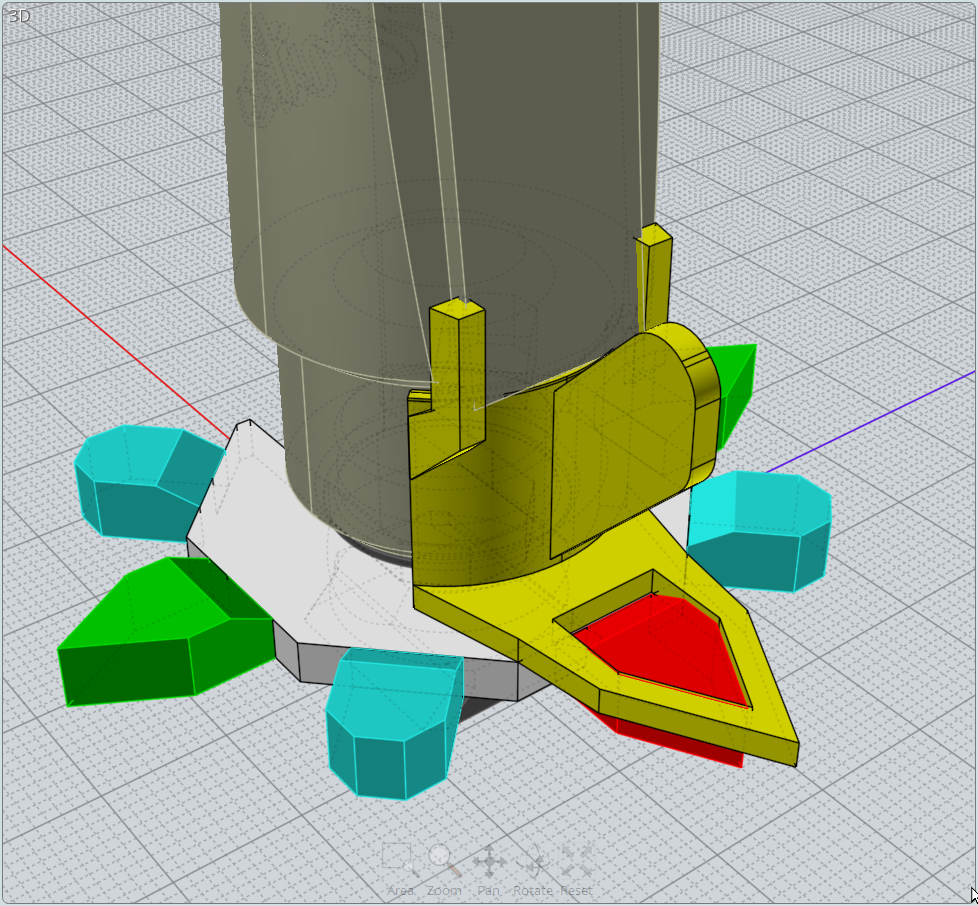

Objects often need to be re-oriented to scan all sides effectively. When this happens, I am assuming that all of the reference objects I am using also need to be re-oriented so that they always line up exactly in the same position relative to the scanned object. Therefore, creating staging tools (bases, swivels, props) that help us do that is a helpful

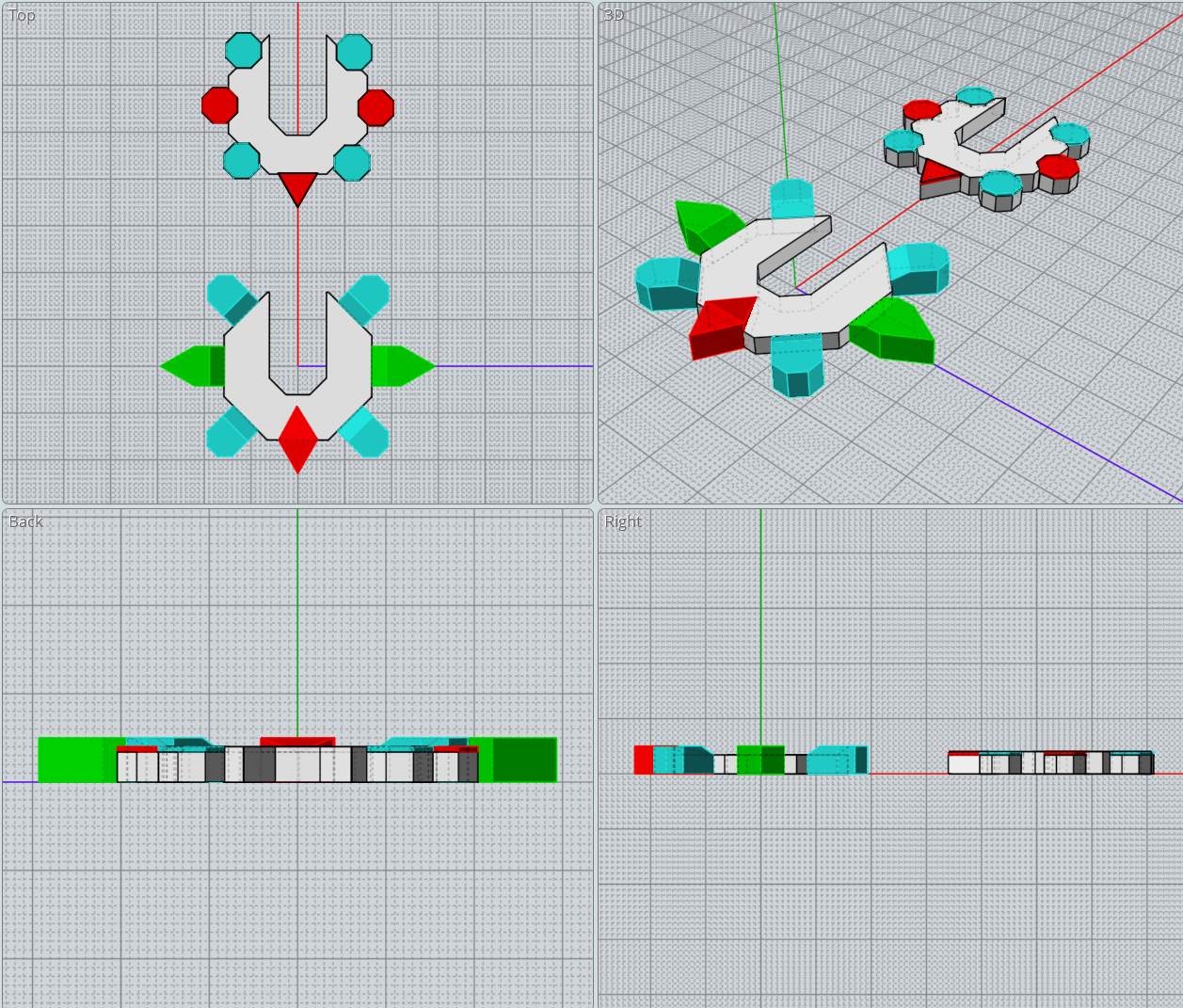

Since multi-color 3D printers are common now, that is what I am using to create my reference features.

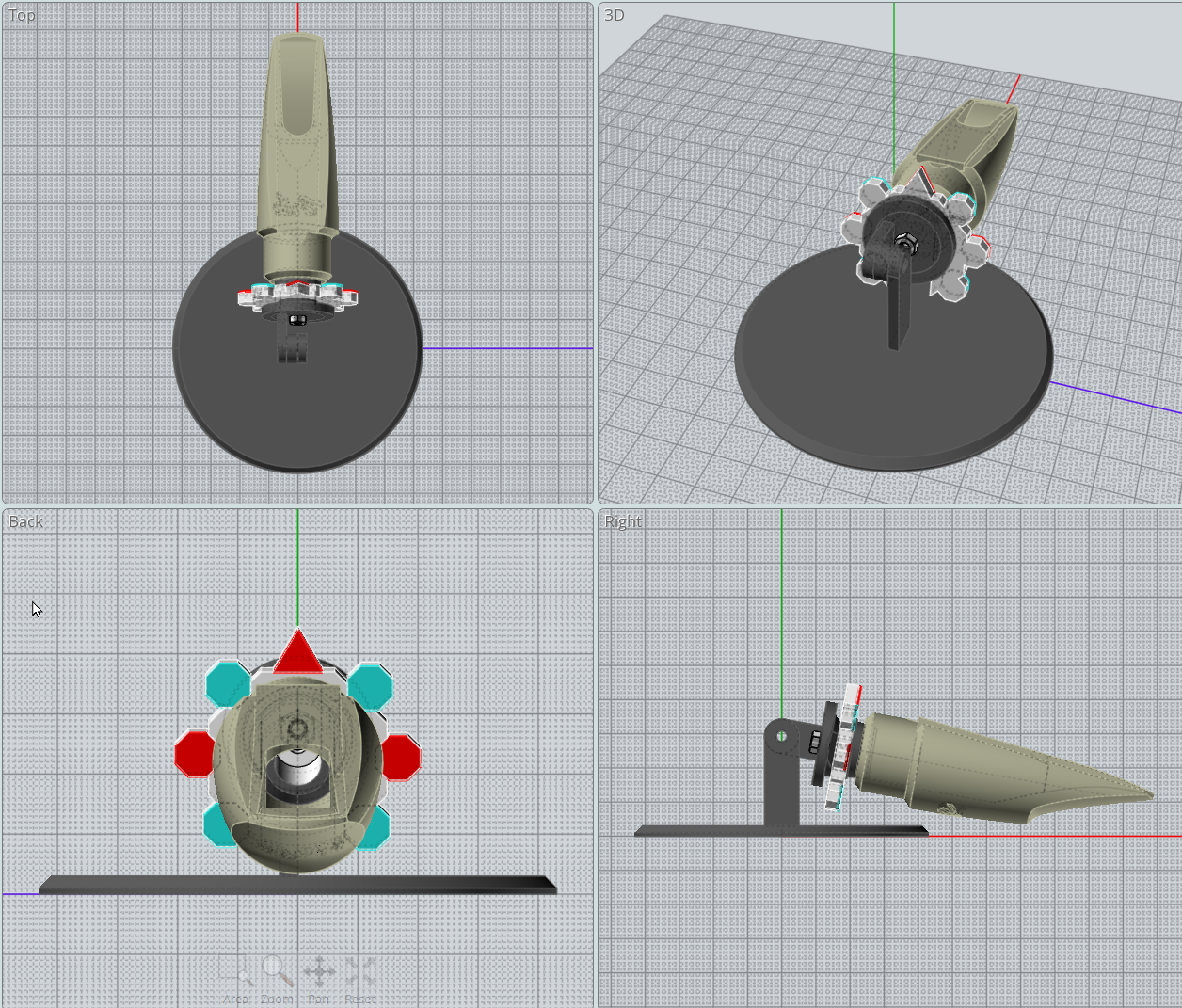

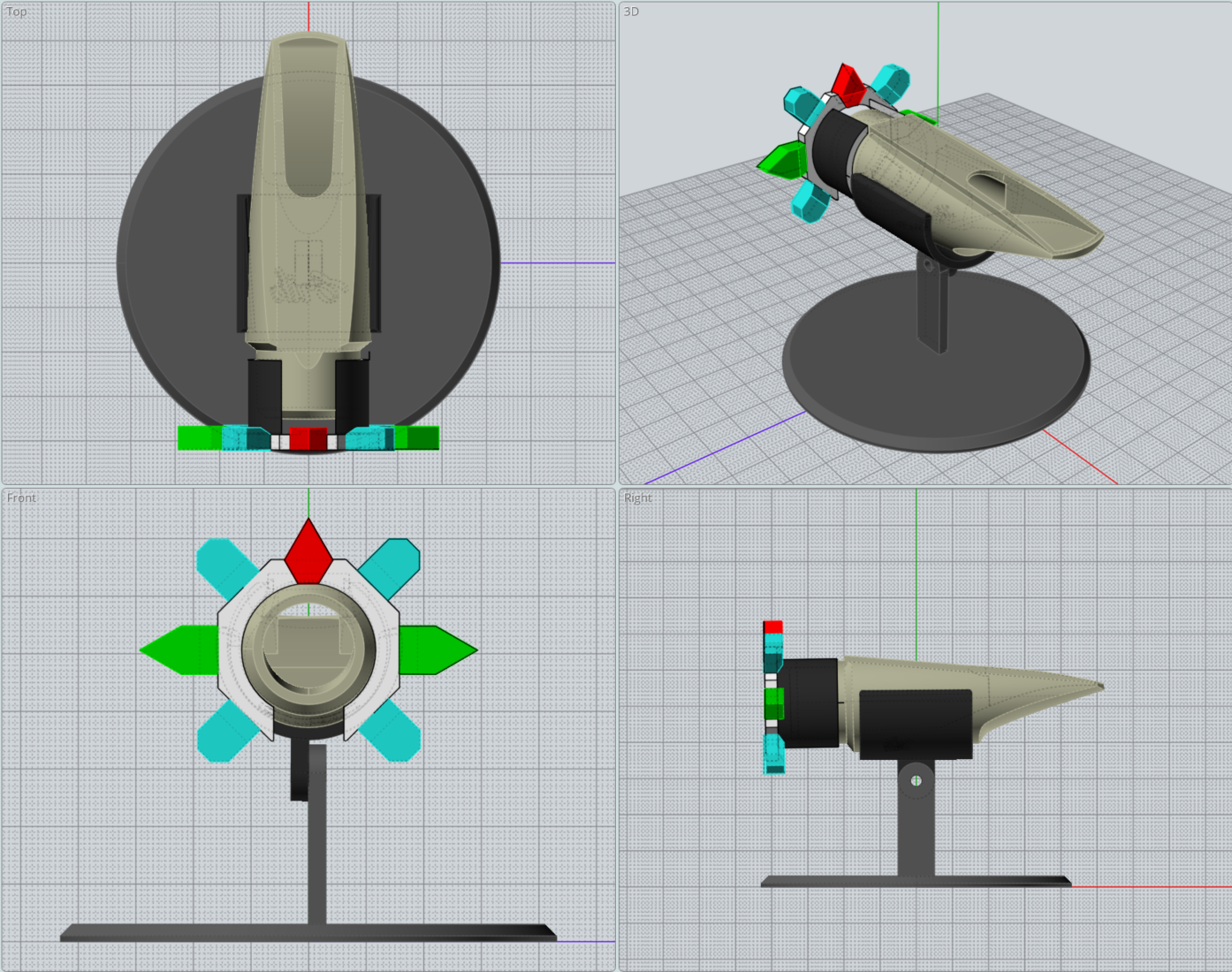

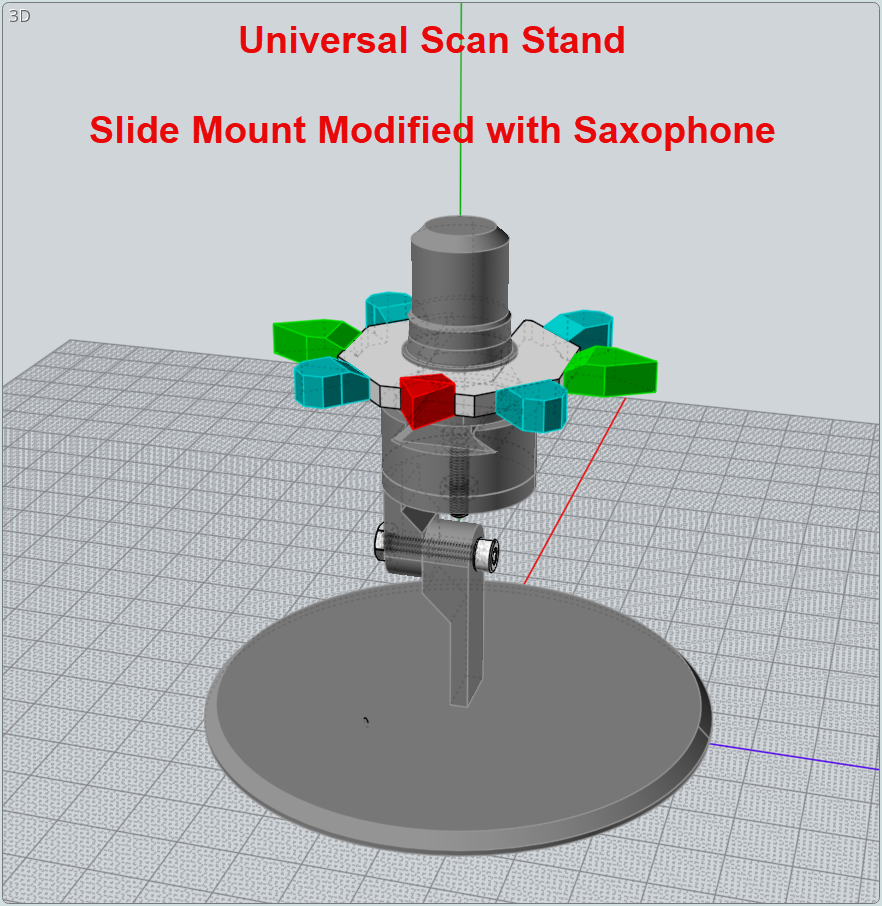

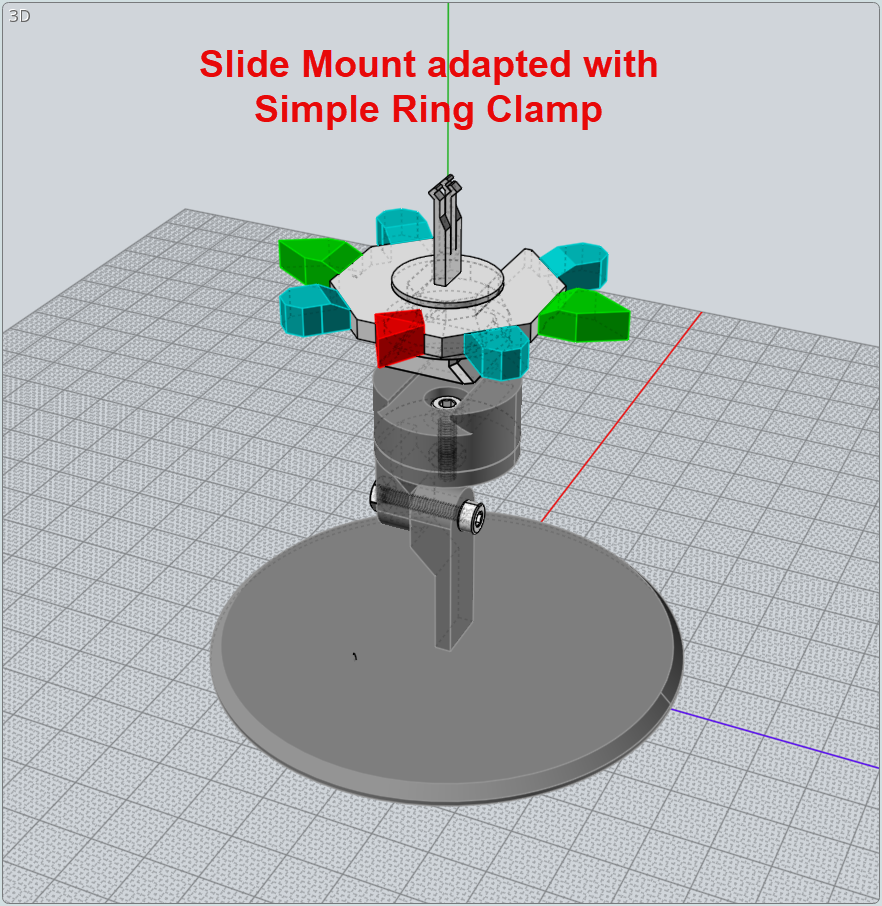

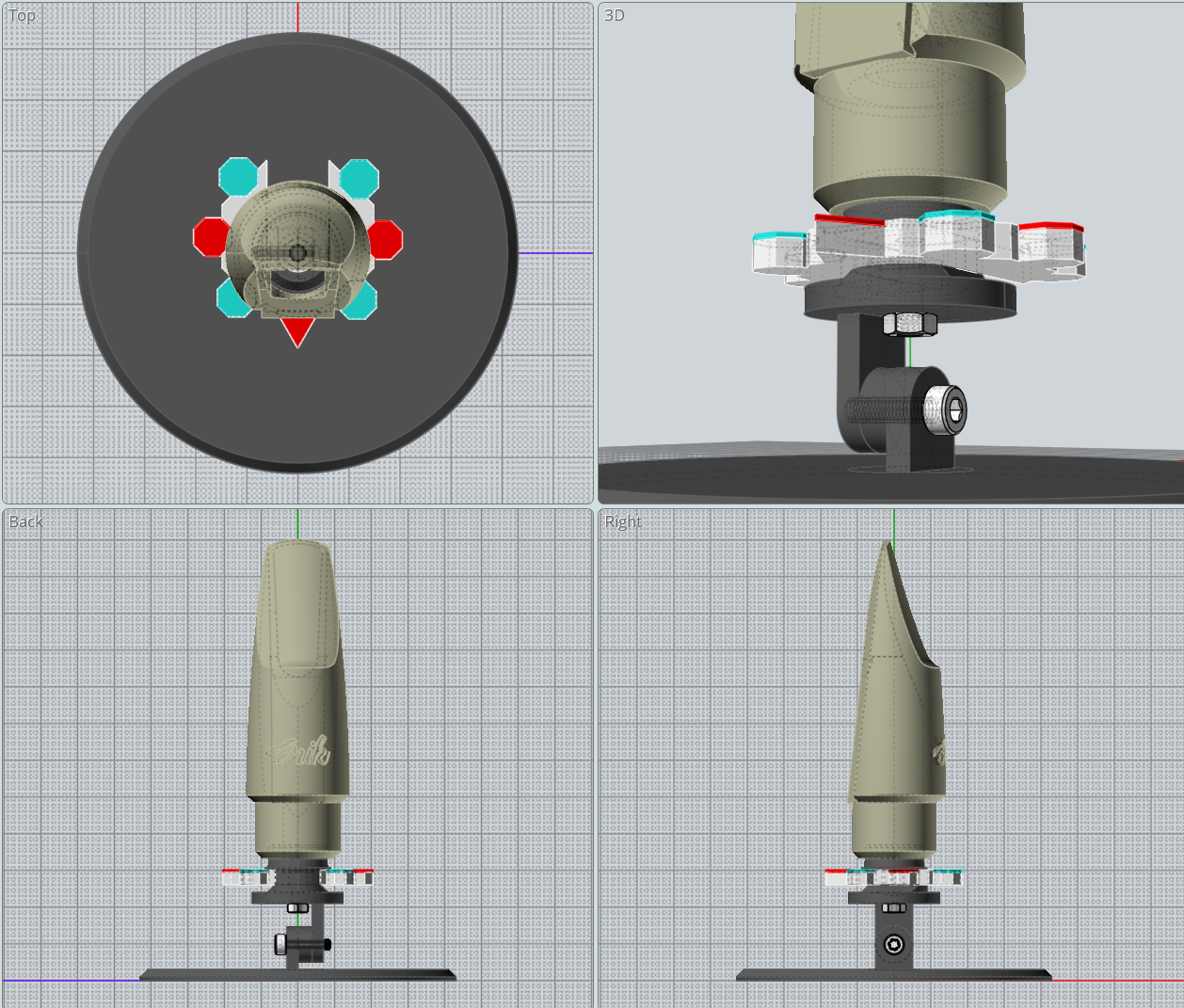

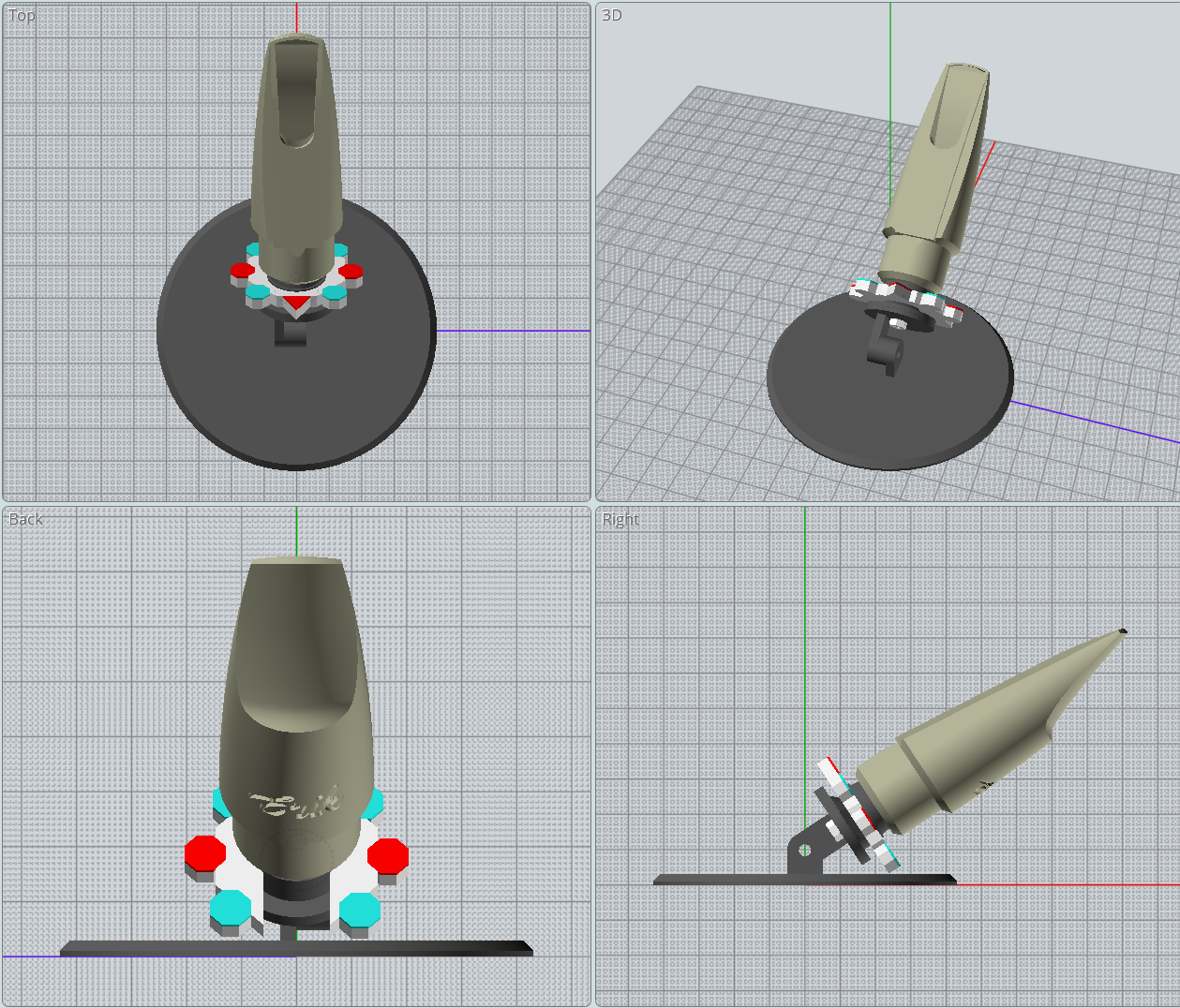

In this case, there is a base that swivels around two axes and a 'reference table' that slides onto the top piece so that it moves with the object being held.

Upright

Angled

While it works, there were some shortcoming in actual practice. The chief being that the short base limited the movement. The other being that the reference table features needed to be more pronounced.