In educating any students; but, in particular, at-risk students, projects that promote critical thinking skills are highly desired. From personal experience, teaching hundreds of at-risk cadets from 4 different localities, there are few disciplines that offer as amny critical thinking possibilities than 3D printing and 3D scanning.

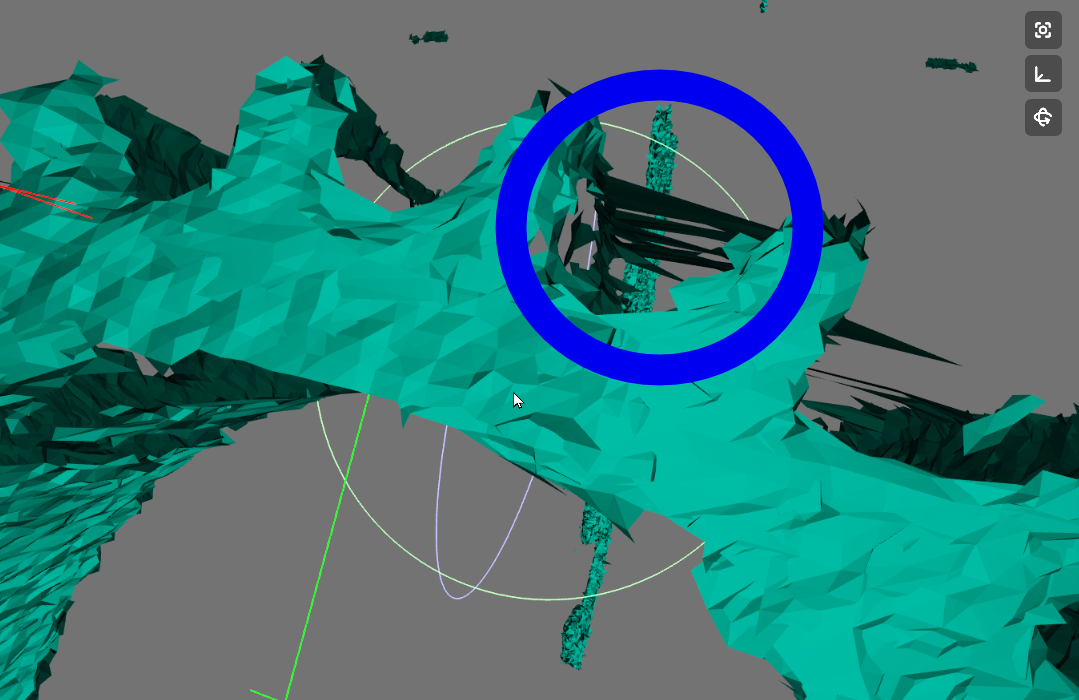

To be successful, ALL 3D scanning projects involve some form of strategy to achive the scanning goals. This is particulary true if the project's goals are set high.

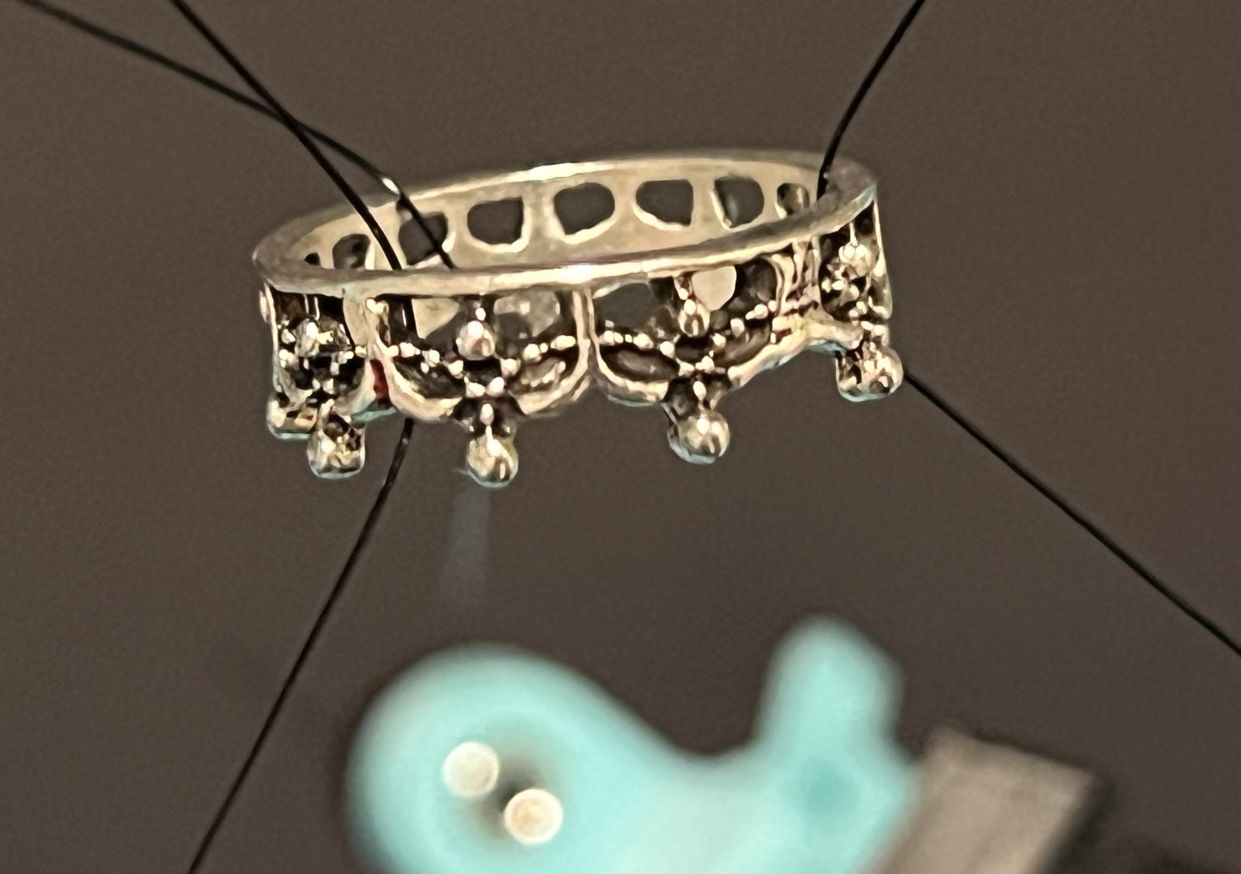

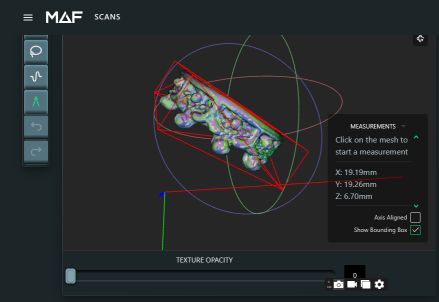

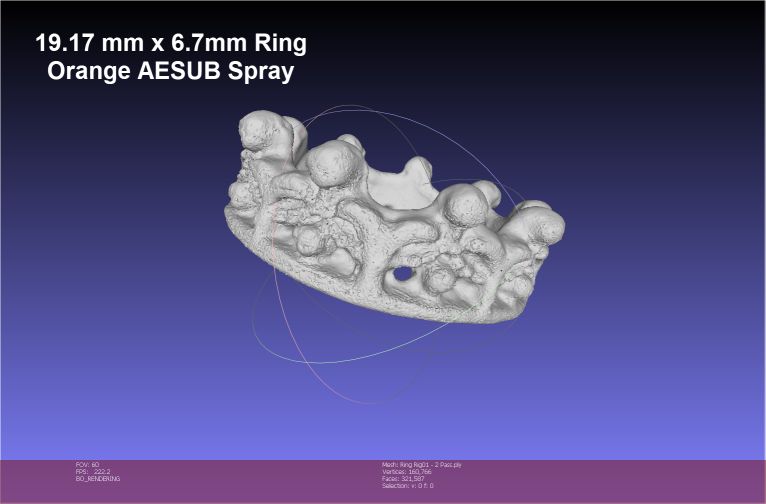

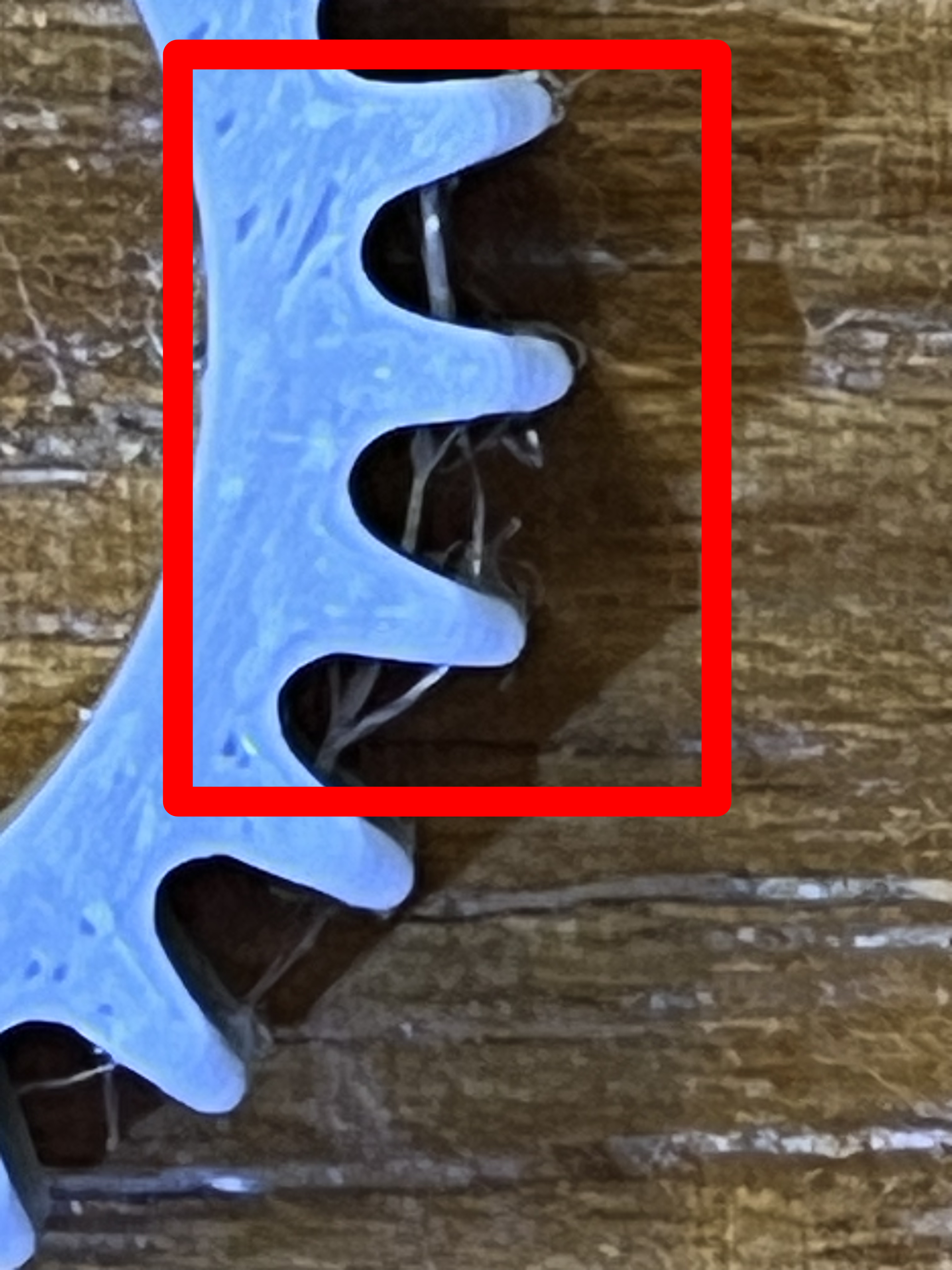

As I was experimenting with scan staging, it quickly became obvious that finding ways to capture every feature of a ring, seemed deceptively simple. But, it's not. Some rings have full patterns that make alignment more difficult than others, etc. So, a high goal, when it comes to scanning rings is this:

Capture ALL features of a complex ring with perfect alignment in every respect.

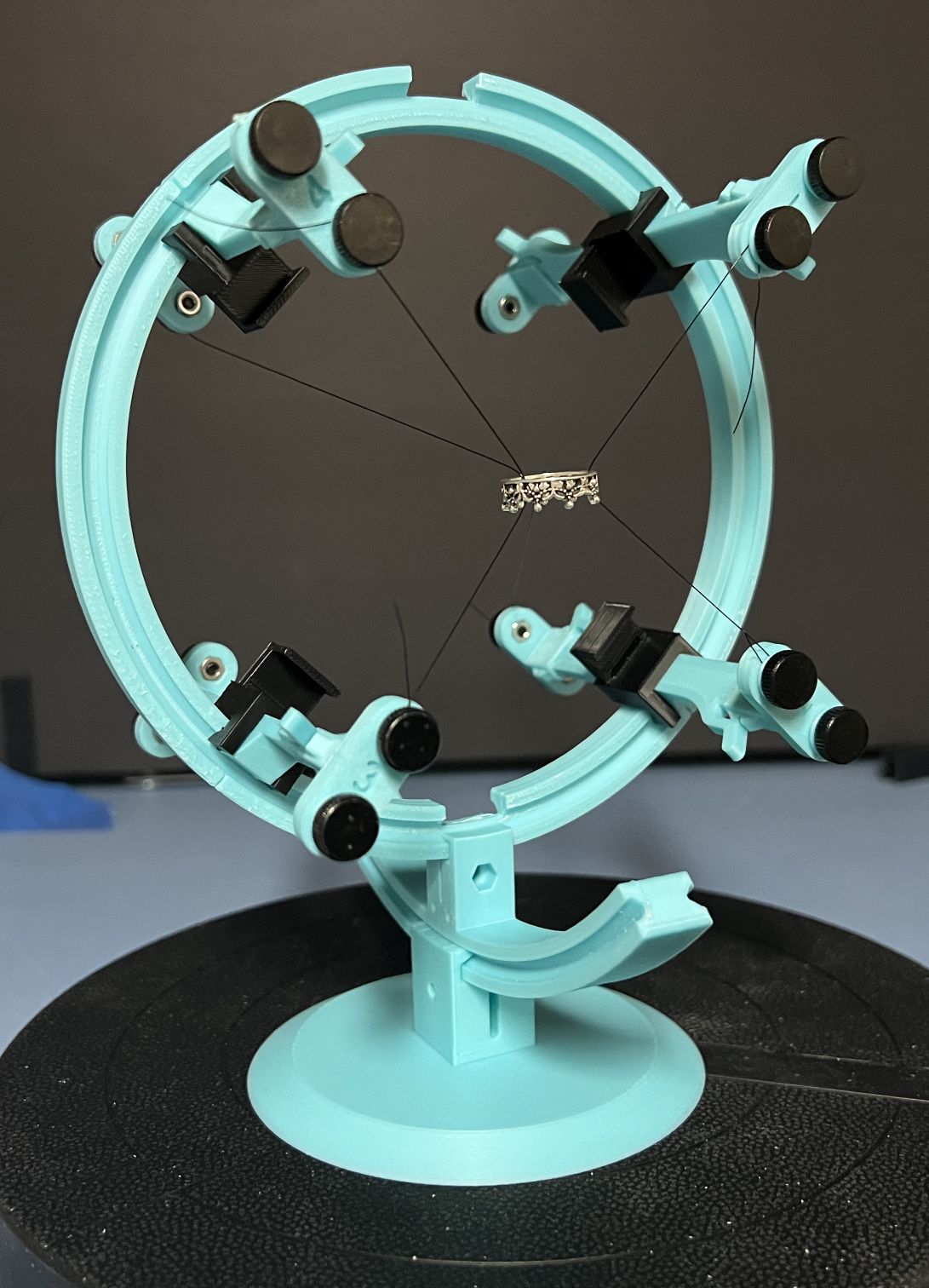

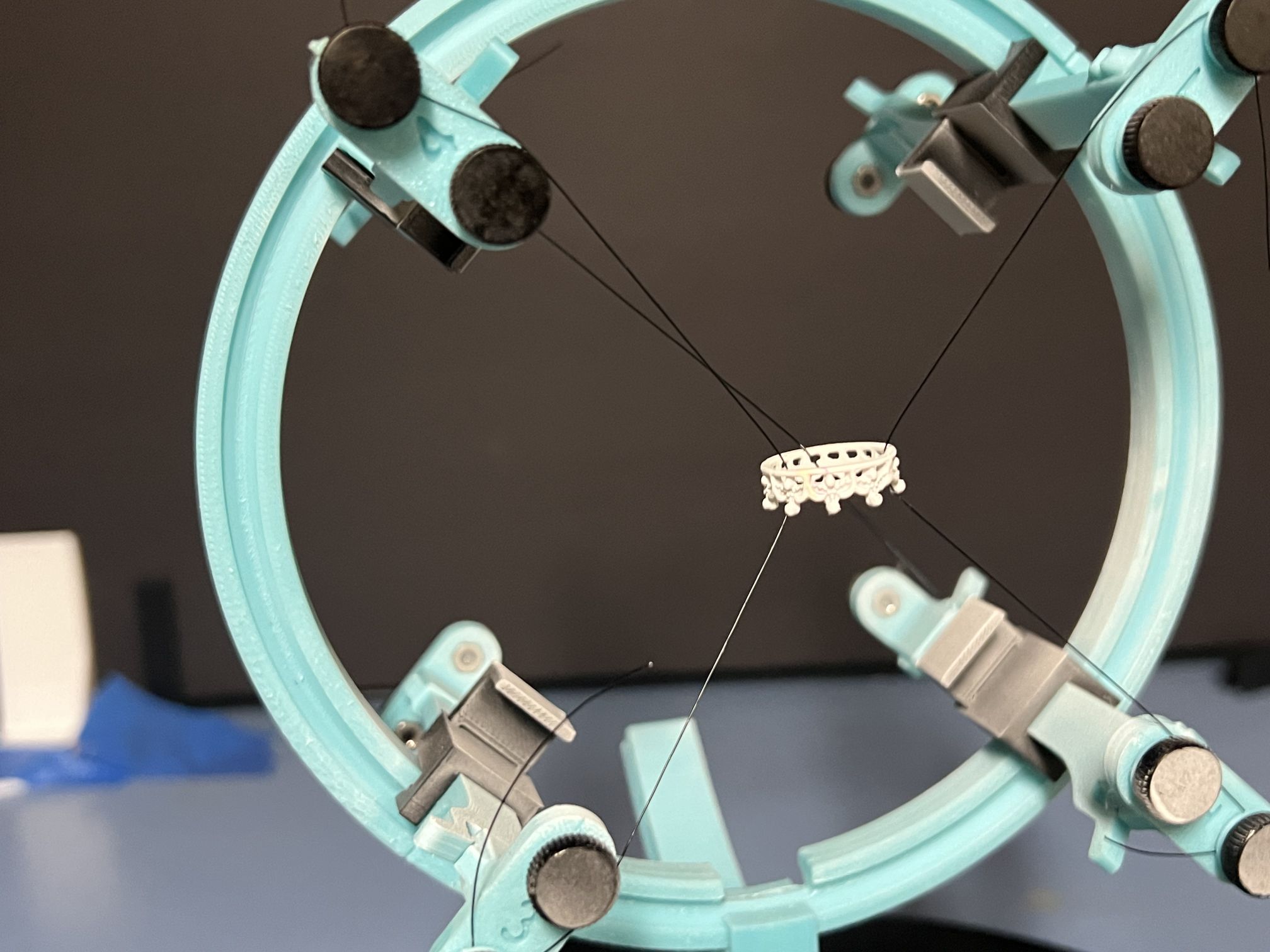

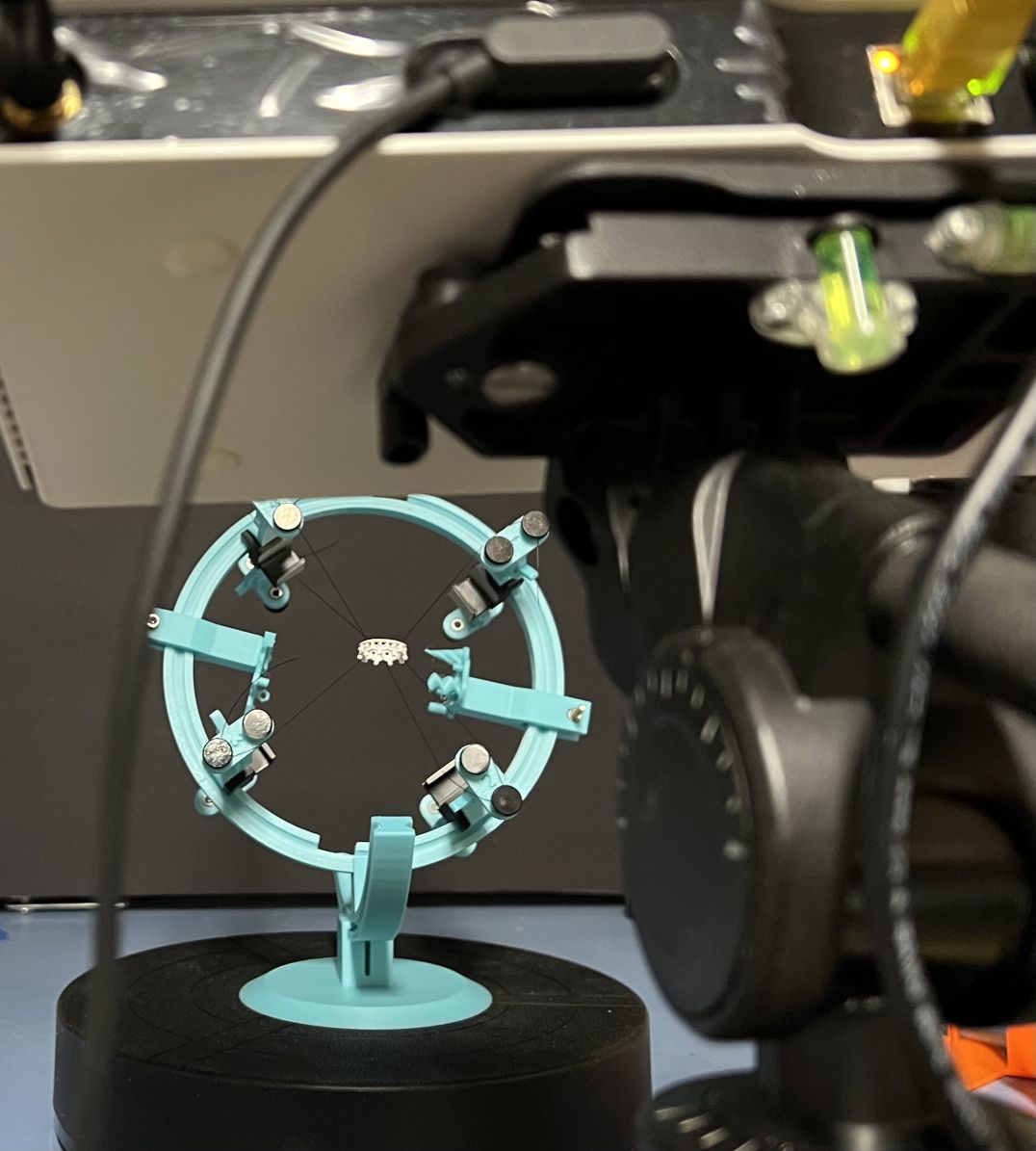

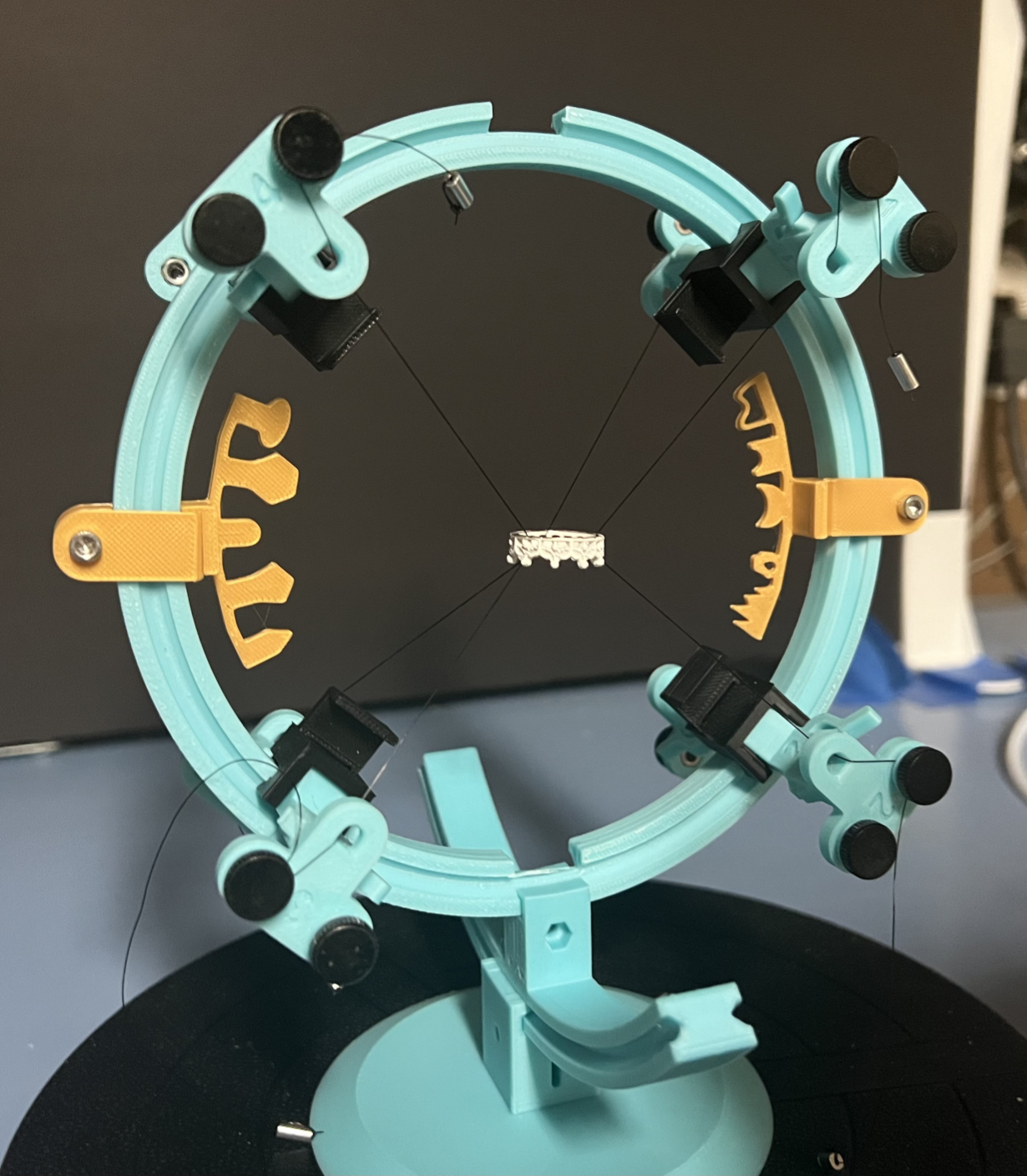

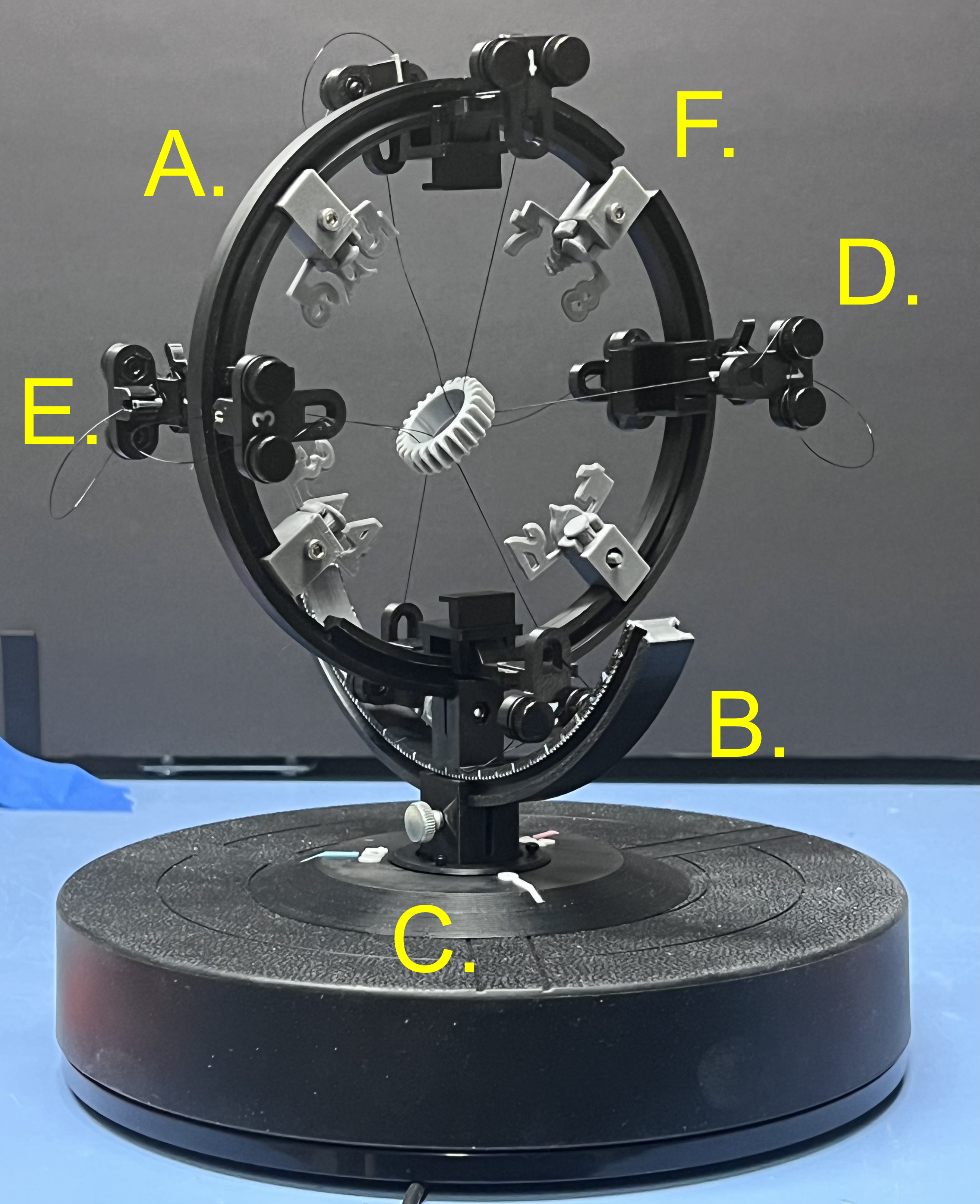

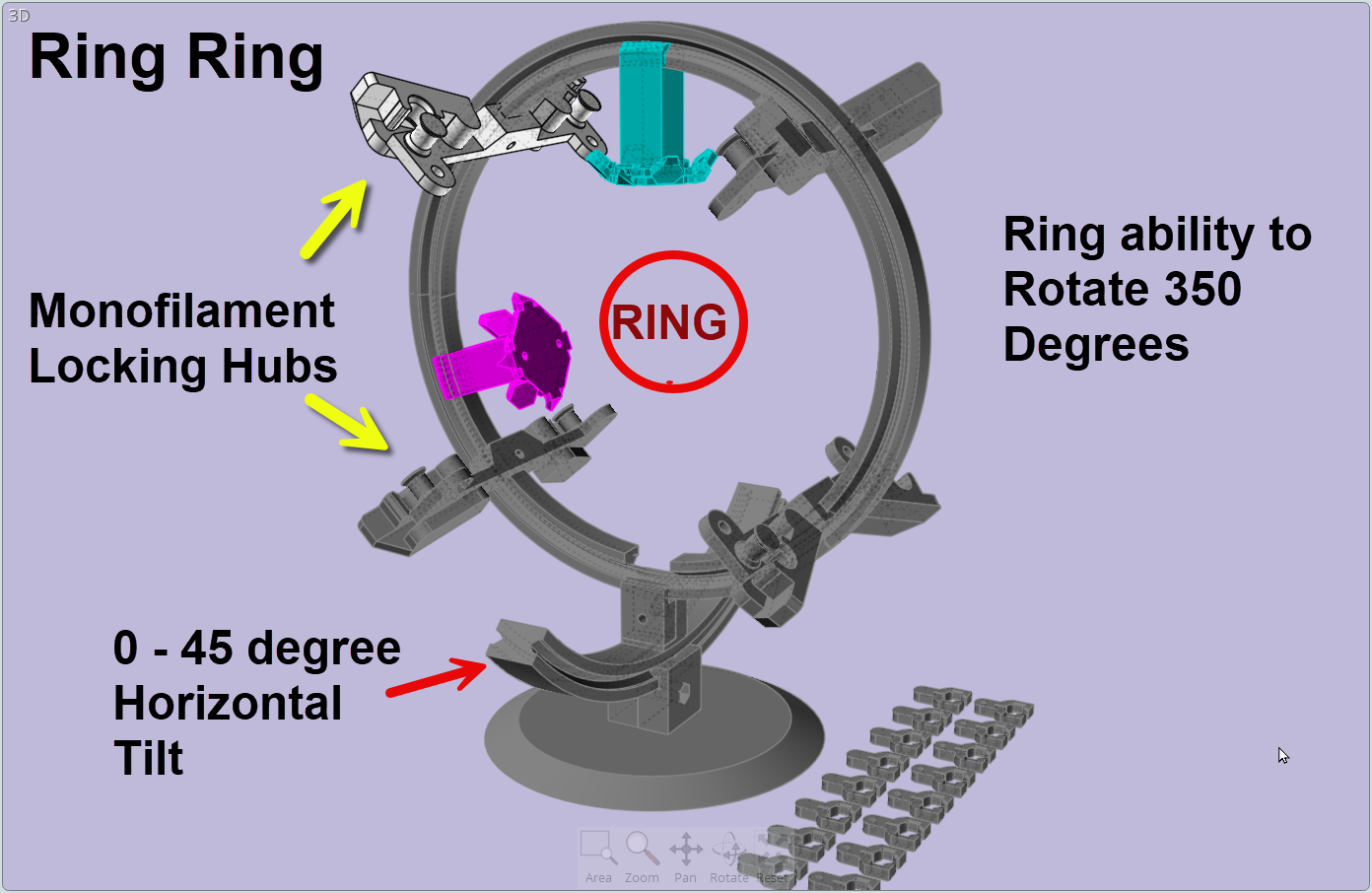

Pursuit of this quest should result in multiple scan 3D staging designs. Most require some significan hardware, like screws and nuts. But, one of the goals I wanted to achieve was to design something that was almost completely 3D printed. The result was this design that still requires two 3mm bolts with nuts.

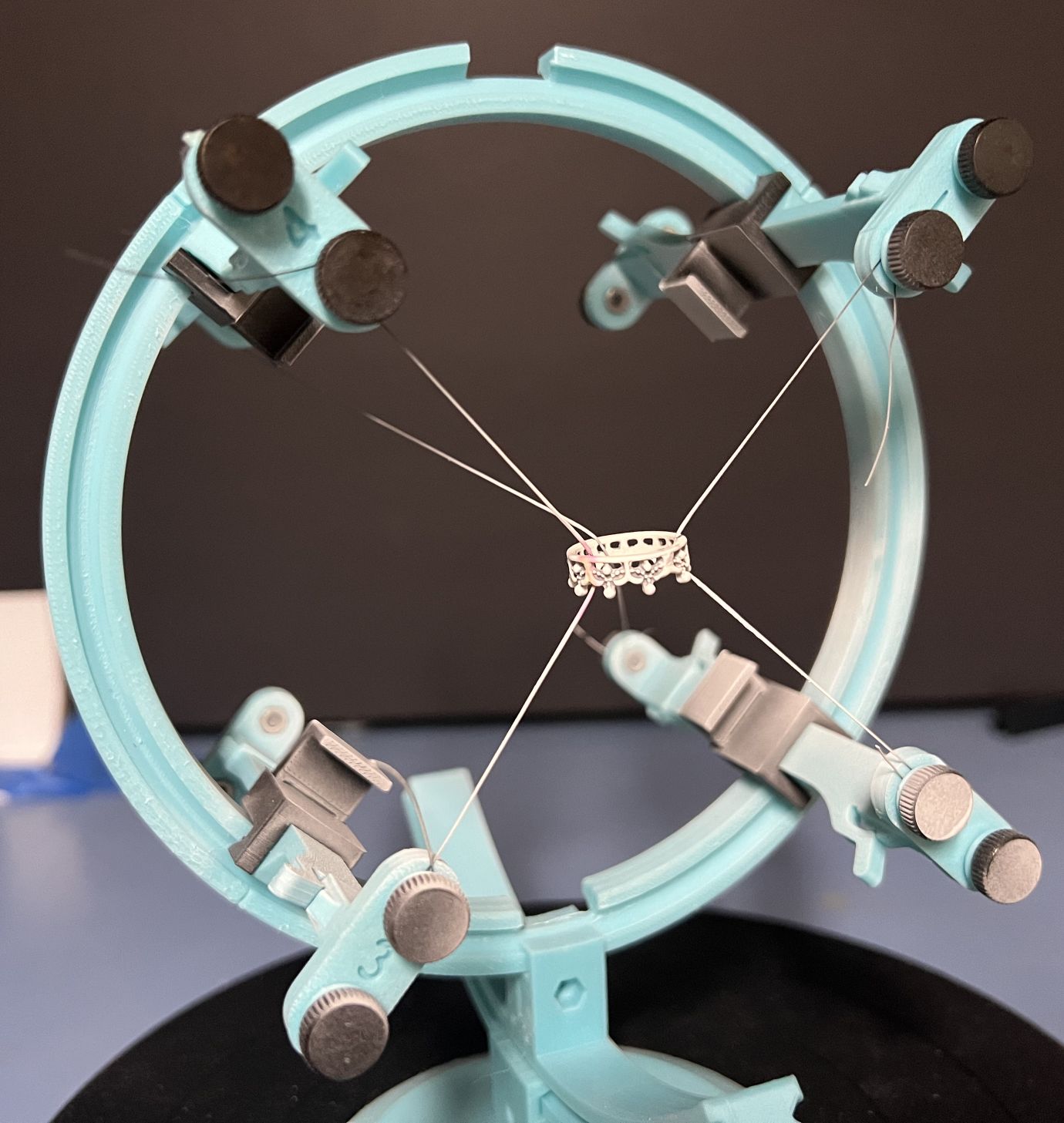

This Ring Ring relies on very thin >.25mm clear monofilament sewing thread to position the target ring near the center of the rotating ring. I will upload the files if it is successful in reaching our goal. (I ran out of time this weekend to try it.)

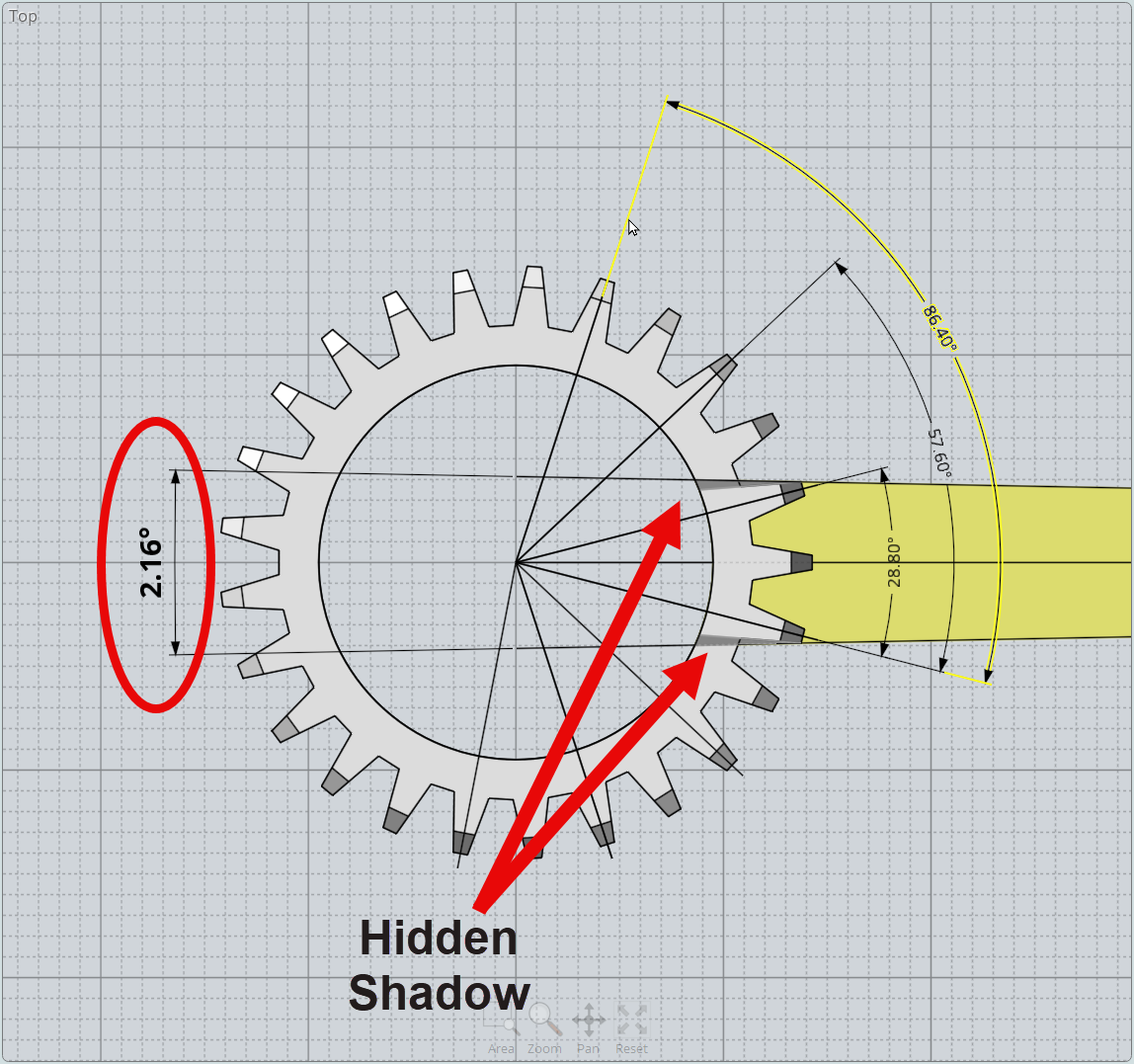

The monofilament is streteched between adjustable outrigger hangers by being wound around hubs and held in place with a locking cover. The question will be just how to run the monofilament to hold the target ring in place tightly with the least interference with scanning the featueres. Considering the possible combinations tests critical thinking skills to the max.

Here is The Ring RING:

Note: The crossbeams can be secured in place with 3mm screws or the small 3D printed sliding locks in the lower right of the image.

Wish me luck.